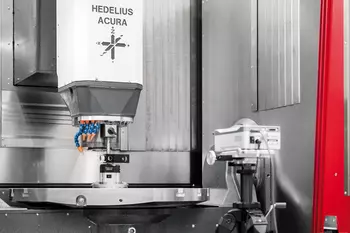

Vertical machining centre FORTE 10-6200

With a 6200 mm X travel path, this machining centre rounds off the successful FORTE 10 series. Generously dimensioned recirculating roller guides, polished ball roller spindles and direct Heidenhain measuring systems in all axes guarantee outstanding rigidity combined with maximum accuracy and dynamics. The travelling column and machine table are made of heavy grey cast iron. This is an essential criterion for an SK50/HSK 100 machine to ensure high surface quality and low tool wear even in difficult-to-machine materials. Thanks to the extensive range of accessories such as rotary tables, vacuum pumps, pick-up magazines for extra-long tools or a hydraulic clamping system for the automatic activation of devices, we can customise the FORTE 10 series to meet your individual requirements.

Your advantages with the FORTE 10-6200

- Extra-large Z-axis travel path of 1,165 mm

- Efficient oscillation mode possible thanks to work area partition

- High table load

- Tool magazine with access to up to 192 tools

- SK50, BT50 or optional HSK A100 tool reception system

- Tool lengths up to 400 mm

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

FORTE 10-6200

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 6200 x 1000 x 1165 mm | - | - | |||

| Oscillation mode | ||||||

| Oscillation mode | 2 x 2765 mm | - | - | |||

| Output | ||||||

| Output | 50 kW | - | - | |||

| Speed range | ||||||

| Speed range | 8000 / 12000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 50, BT 50, HSK A100 | - | - | |||

| Capacity | ||||||

| Capacity | 40 / 192 | - | - | |||

| Contact surface | ||||||

| Contact surface | 6680 x 1000 mm | - | - | |||

| Fixed machine table max. load | ||||||

| Fixed machine table max. load | 8000 kg | - | - | |||

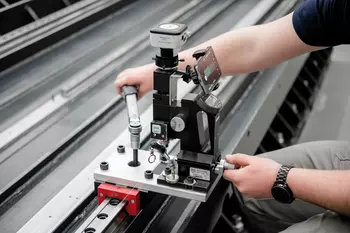

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.